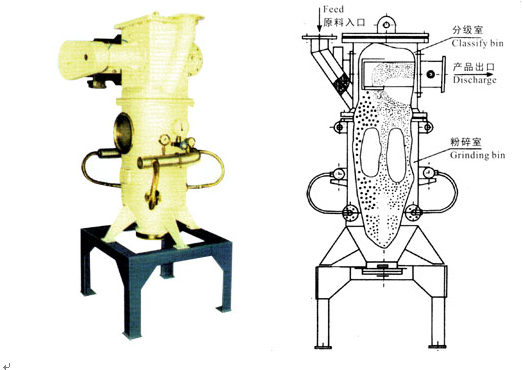

The material enters the crushing chamber, and the supersonic jet flow forms a centripetal reverse jet flow field at the lower part of the crushing chamber. Under the action of the pressure difference, the bottom material is fluidized, and the accelerated material converges at the intersection of the multi-nozzle, resulting in a violent explosion. The crushed fine powder moves with the airflow to the upper turbine classifier, and under the action of centrifugal force, the fine powder that meets the fineness requirements is discharged.

QLD type fluidized bed jet mill integrates the mechanisms of crushing, classification, mixing and homogenization, and realizes the unique advantages of on-line operation. • High impact speed, the particles collide and impact after being accelerated by the airflow nozzle, the impact speed is the superposition of two relative speeds, and the crushing efficiency is high.

Low energy consumption, compared with other types of jet mill, can save one third of energy.

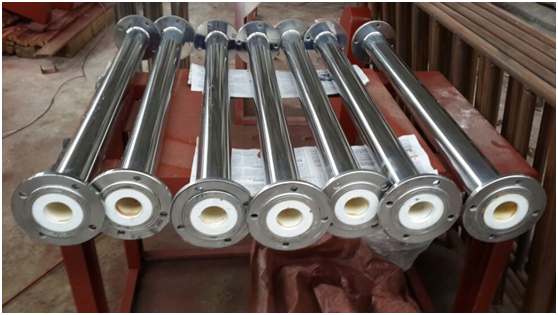

The wear is extremely small. Since the main crushing effect is the mutual impact and collision of particles in the fluidized bed, the high-speed particles rarely collide with the grinding wall and the material does not pass through the nozzle, which can be used for the crushing of high-hardness materials. The inside of the cylinder is made of ceramic material, and the installation of ceramic grading wheels is more suitable for the crushing of high-purity materials (such as battery materials, alumina, zirconia, etc.).

The built-in turbo-type superfine classifier has high classification accuracy and narrow product particle size distribution range.

Automatic control function, the operation is very convenient.

Low noise.

Compact structure and small footprint.

| Material Properties | Material Name (Representative Example) |

| High Purity Material | Phosphor Special Ceramic Silica Gel Alumina |

| High Hardness Material | Tungsten Carbide Silicon Carbide Boron Carbide Tungsten Oxide Zirconia Silicon Oxide Emery |

| Heat Sensitive Material | Toner Pesticides |

| Plastic Material | Various resin products |

| Difficult to Crush Materials | Flake Mica Graphite Talc |

| high Density Porous Material | Silica Gel |

|

Parameter |

Model |

||||||||

|

QLD100 |

QLD250 |

QLD 350 |

QLD 450 |

QLD 680 |

|||||

|

Pulverizing Pressure(Mpa) |

0.6-1.2 |

0.6-1.2 |

0.6-1.2 |

0.6-1.2 |

0.6-1.2 |

||||

|

Air Volume (m3/min) |

1.8-3.6 |

4-7.2 |

8-12 |

16-22 |

33-44 |

||||

|

Capacity (Kg/h) |

2-10 |

10-100 |

20-250 |

50-500 |

120-1500 |

||||

|

Speed of Classifier(r/min) |

22000 |

16000 |

8000 |

6000 |

4000 |

||||

|

Particle Size (μm) |

2-50 |

2-50 |

2-50 |

2-50 |

2-50 |

||||

|

Dimension(mm) |

510×560×1670 |

400×550×1250 |

600×750×1620 |

1030×970×2014 |

1140×1075×2504 |

||||

|

Weight (Kg) |

150kg |

180 |

270 |

530 |

970 |

||||

|

System Powder(Kw) |

-20kw |

37-45 |

65-90 |

132-160 |

300-335 |

||||

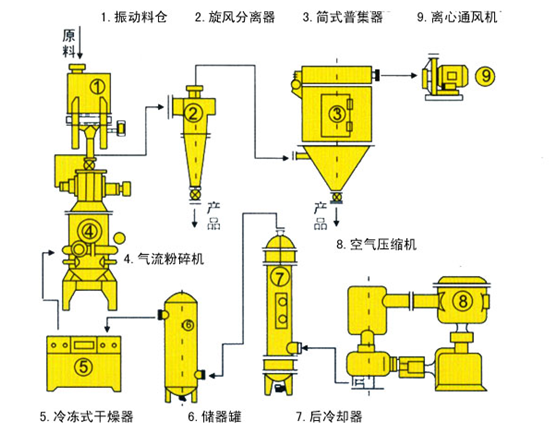

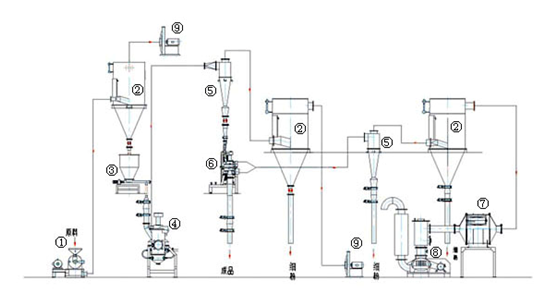

QLZ fluidized bed jet mill is a new generation of ultra-fine jet mill. It integrates the most advanced multi-nozzle technology, fluidized bed technology and vertical classification technology in the world, and realizes the diversification of the flow field, the fluidization of the material layer, the vertical classification of the classification and the mechanical and electrical integration technology system. The development direction of grinding. The biggest features are:

1. The distribution of PSD particles is more concentrated;

2. The weight control method is adopted to maximize the output. The production line formed with the FSZ type classifier is widely used in the production of printers and copy toner (toner).

|

Model |

Air Consumption |

Work Pressure |

Processing Power |

|

QLZ100 |

3.5m3/min |

0.6-0.9Mpa |

2-10kg/h |

|

QLZ350 |

10-12m3/min |

0.6-0.9Mpa |

10-100kg/h |

|

QLZ450 |

18-25m3/min |

0.6-0.9Mpa |

30-400kg/h |

|

QLZ680 |

45-55m3/min |

0.6-0.9Mpa |

100-1500kg/h |

1- Coarse Pulverizer

2- Trap

3-Screw Feeder

4-QLZ450 Fluidized Bed Jet Mill

5-Cyclone Separator

6-FSZ400 Classifier

7-Roots Fan Filter

8-Roots Blower

9- Fan

+86-21-64071149

+86-64481019

+86-64481022

No. 2094, Huan'an, Huanxing Village, Jinshan Industrial Zone, Jinshan District, Shanghai