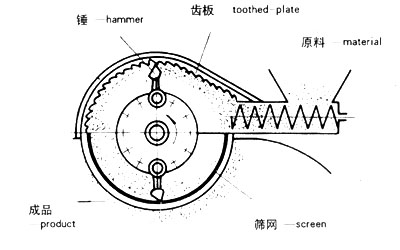

The machine uses a pendulum that rotates rapidly around the horizontal axis. According to the shape of the grooves of the lining tooth plate, the rotation of the rotor forms a cyclonic vortex field in each groove, and the vortex direction is opposite to the main vortex formed by the rotor. , so that the particles collide and collide with each other, the particles collide with the pendulum to further pulverize the material, and the fine particles are discharged through the discharge screen. .

On the other hand, the gap between the front end of the pendulum and the lining tooth plate also plays a shearing role, so this machine can be widely used for the crushing of tough materials and fibrous materials.

JCW610 hammer type mechanical pulverizer is suitable for chemical, dye, pesticide, food, beverage and other industries, and is widely used in carbon black industry. The crushed materials are minerals, organic and inorganic chemicals, pharmaceuticals, fiber materials and plastics.

| Model \ Parameters |

Rotating Speed (r/min)

|

Production Capacity (kg/h)

|

Power(kw)

|

Powder Fineness(um)

|

| JCW610 |

3500

|

500-1500

|

37

|

45

|

| JCW610-VI |

3450

|

1000-3000

|

110

|

45

|

The material enters the inner cavity of the machine through the screw feeder, and the vortex field formed by the pendulum rapidly rotating around the horizontal axis and the groove of the toothed plate is used. The vortex direction is opposite to that of the main vortex formed by the rotor. Impact each other, and also collide with the pendulum to smash. On the other hand, the narrow gap between the front end of the hammer head and the toothed plate also plays a shearing role, and a few powder particles that have not passed the hammer are crushed by the eddy current formed by the upper and lower toothed plates, and finally the fine particles are discharged through the screen.

The JCW300 micro-grinder is mainly used for the crushing of various soft minerals, brittle materials, fibrous materials and other solid materials with a Mohs hardness of about 3, as well as the crushing of materials that are easy to agglomerate into blocks.

Various chemicals, dyes, paints, pigments, building materials, pesticides, fertilizers, marine products, pharmaceuticals, herbs, carbon black, feed, fibers, leather, paper, precious metals, sanitary materials, spices, etc.

1. The shell of the JCW300-I micro-pulverizer is designed with a water cooling interlayer, which can reduce the temperature in the pulverizing cavity during operation.

2. The discharge can use a variety of aperture screens for users to choose, and can also choose to be equipped with a strip screen. Different air volume and air pressure can obtain the required classification particle size. 3. It is also specially designed with a combination type, which occupies a small area and is easy to operate.

| Parameters \ Model | JCW300-I | JCW300-II |

| Crushing Chamber Diameter(mm) | 300 | 300 |

| Motor Power(kW) | 15 | 18.5 |

| Spindle Speed(r/min) | 6500 | 6500 |

| Hammer Count | 1 In 12 Hammers | 2 In 24 Hammers |

| Standard Air Volume(m3/min) | 1174 | 1610 |

| Production Capacity(Kg/h) | 20-400 | 100-600 |

| Pulverized Particle Size(um) | ≥43 | ≥43 |

| Dimensions(mm) | 1480X1280X1490 | 1475X1465X1485 |

| (Kg) | 750 | 950 |

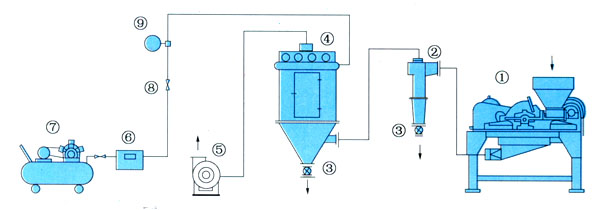

1. JCW300 Micro Pulverizer

2. Cyclone Collector

3. Rotary Discharge Valve

4. Pulse Bag Collector

5. Centrifugal Fan

6. Air Source Treatment Device

7. Air Compressor

8. Pressure Reducing Valve

9. Pressure Gauge

+86-21-64071149

+86-64481019

+86-64481022

No. 2094, Huan'an, Huanxing Village, Jinshan Industrial Zone, Jinshan District, Shanghai