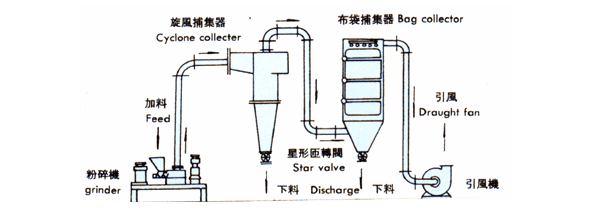

The whole machine of double-shaft micro pulverizer is vertical, and there are pulverizing chamber and grading chamber in the machine. Its structure and working principle are shown in the figure.

When working, the air is drawn at the discharge pipe to generate negative pressure, and the quantitative screw feeder pushes the material in the door into the crushing chamber, and the powder enters the grading chamber through the guide ring.

Because the classification wheel is rotating, the powder flowing into the blade channel is affected by aerodynamic force and centrifugal force at the same time.

The particles larger than the critical diameter (classified particle size) in the powder are thrown back into the pulverizing chamber due to their large mass and continue to be pulverized, and the particles smaller than the critical diameter enter the collection system through the discharge pipe.

The JCL double-shaft micro-grinder has a compact design and a reasonable structure. The machine is equipped with an internal grading mechanism, so that the grinding and grading can be completed at one time, so as to reduce the energy loss caused by over-grinding.

The machine system is equipped with an induced draft fan, which can continuously discharge the heat generated in the machine during the crushing operation, so it is suitable for the crushing of heat-sensitive materials.

This machine has strong adaptability and narrow particle size distribution, and can handle the crushing of materials such as chemicals, food, medicine, pharmaceuticals, cosmetics, plastics, dyes, resins, pigments, grains, etc.

x

x

|

Model/Parameter |

Monitor Rate(Kw) |

Rated Speed(r/min) |

Production Capacity(kg/h) |

Grinding ineness(μm) |

|

JCL320 |

7.5 |

6880 |

100-400 |

45 |

|

JCL520 |

22 |

4200 |

100-800 |

45 |

|

JCL800 |

45 |

2800 |

200-1000 |

10-30 |

+86-21-64071149

+86-64481019

+86-64481022

No. 2094, Huan'an, Huanxing Village, Jinshan Industrial Zone, Jinshan District, Shanghai