The material is fed into the grading chamber by the rotary valve beside the upper cylinder through the feeding port. Dispersion and classification beside the horizontally installed rotor. The coarse powder is thrown to the wall of the cylinder and moves downward, and is blown by the secondary air at the air grid and the primary air of the central pipe. The fine powder is separated from the coarse powder again and sent to the rotor for classification. Finally, the coarse powder moves downward and is discharged out of the machine through the rotary valve on the lower cylinder. The fine powder passes through the gap between the rotor blades and is sent out of the machine through the exhaust pipe. The exhaust gas in the trap is released to the atmosphere by the fan.

This machine is a dry air classifier. It is a centrifugal classifier with secondary air inlet and horizontal installation. It has strong wear resistance and long service life. Generally suitable for the classification of non-sticky materials.

Even products that are not easily dispersed in the air can be classified to obtain fine and coarse powders with the best cleanliness (that is, with minimal entrainment of fine and coarse powders).

A wide range of grading. Available in the range of d97=4-150um, the maximum production capacity can reach 8t/h, and it can be widely used in cement manufacturing.

It can classify spherical, flake and fibrous particles, and can also separate materials of different densities.

High classification accuracy: d75/d25=1.1-1.5

High classification efficiency: Newton efficiency η=60-90%

The structure of the equipment is compact, and the particle size of the classification is easy to adjust. And installation, operation, maintenance, cleaning is simple, small footprint, low ultrasonic, small vibration.

The production capacity is large. When the preparation of d97=10um, the production capacity can reach more than 1000Kg/h. It can work in conjunction with various mechanical pulverizers and jet pulverizers such as Raymond mill to produce ultrafine powder.

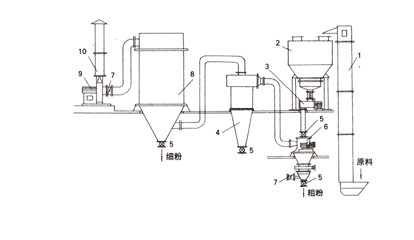

1. Bucket Elevator (Feeder)

2. Vibration Silo

3. Screw Feeder

4. Cyclone Separator

5. Star Valve

6. FYW Classifier

7. Butterfly Valve

8. Pulse Bag Filter

9. High Pressure Fan

10. Muffler

| Parameter Model |

Rotor Diameter (mm) |

Rotor Motor Power(kw) | Production Capacity (kg/h) | Maximum Speed (r/min) | Air Volume(m3/min) | Mainframe Dimensions (mm) | Host Weight (Including Motor)(kg) |

Fan Power (kw) |

D97 |

| FYW300 | 150 | 4 | 20-200 | 8000 | 12.9 | 850X700X1120 | 300 | 11 | 4-80 |

| FYW400 | 200 | 5.5 | 50-400 | 6000 | 16.6 | 1030X840X1600 | 400 | 5-120 | |

| FYW630 | 315 | 11 | 200-2500 | 4000 | 42 | 1080X1200X1744 | 600 | 18.5 | 6-150 |

| FYW850/4 | 200X4 | 5.5X4 | 800-4000 | ≥6000 | 100 | 1400X1400X2196 | 2500 | 75 | 4-150 |

| FYW1000 | 500 | 15 | 1000-8000 | 2400 | 125 | 2280X1626X2808 | 2130 | 55 | 8-150 |

| FYW1250 | 630 | 22 | 1000-5000 | 2000-200 | 160 | 3500X2200X3300 | 3500 | 75 | 8-150 |

+86-21-64071149

+86-64481019

+86-64481022

No. 2094, Huan'an, Huanxing Village, Jinshan Industrial Zone, Jinshan District, Shanghai